What Is An Automatic Tube Filling Machine?

What Is An Automatic Tube Filling Machine?

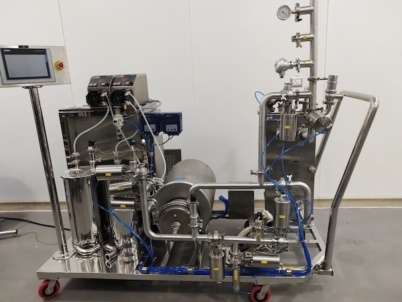

This is a machine that automatically feeds empty tubes into a table with rotary indexing and aligns them in a specific manner. It then fills a defined product into the tubes and seals them using methods like folding, heat sealing or trimming.

Tube packaging is popular in modern industrial settings. Therefore, choosing an effective and reliable automatic tube filling machine will guarantee safe packaging, better branding and reliability.

How To Select The Right Tube Filling Machine?

Tube Filling Machines have various designs and shapes available in the market with different sizes and capacities.

Some of the main factors to consider when sourcing for this machine include:

Production Capacity

The most important thing, is to understand your production needs to choose the right machine which will fulfill your requirement and targets.

Material and construction

The type of material for manufacturing this machine is one of the most important elements that you must consider.

Stainless steel is mostly preferred because of its ability to withstand corrosion, heat and extreme weather.

Quality and safety

When buying this unit, an important aspect you must always look into is whether or not it meets the recommended quality and safety standards.

The operators will be assured of their safety in operation while the machine will provide quality performance and efficiency.

We are regularly exporting to Bangladesh, Nepal, Egypt, Ghana, Nigeria, Iran, Iraq, Nigeria, Kenya, Ukraine, UAE, Turkey.

Enquiry Now

What Is An Automatic Tube Filling Machine?

What Is An Automatic Tube Filling Machine?

This is a machine that automatically feeds empty tubes into a table with rotary indexing and aligns them in a specific manner. It then fills a defined product into the tubes and seals them using methods like folding, heat sealing or trimming.

Tube packaging is popular in modern industrial settings. Therefore, choosing an effective and reliable automatic tube filling machine will guarantee safe packaging, better branding and reliability.

How To Select The Right Tube Filling Machine?

Tube Filling Machines have various designs and shapes available in the market with different sizes and capacities.

Some of the main factors to consider when sourcing for this machine include:

Production Capacity

The most important thing, is to understand your production needs to choose the right machine which will fulfill your requirement and targets.

Material and construction

The type of material for manufacturing this machine is one of the most important elements that you must consider.

Stainless steel is mostly preferred because of its ability to withstand corrosion, heat and extreme weather.

Quality and safety

When buying this unit, an important aspect you must always look into is whether or not it meets the recommended quality and safety standards.

The operators will be assured of their safety in operation while the machine will provide quality performance and efficiency.

We are regularly exporting to Bangladesh, Nepal, Egypt, Ghana, Nigeria, Iran, Iraq, Nigeria, Kenya, Ukraine, UAE, Turkey.