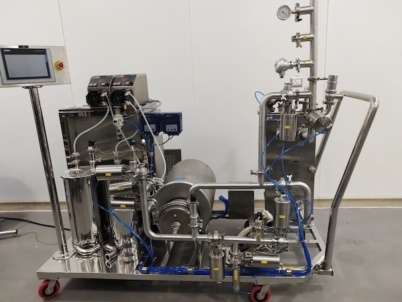

Description

CIP System and SIP System are systems intended for automatic cleaning and purifying without significant disassembly and construction work. Clean-in-Place (CIP) system is a method of cleaning the interior surfaces of pipes, vessels, process equipment, filters and associated fittings, without disassembly. We design, produce, production, supply and fit Mobile and Fixed CIP and SIP System for sanitization. The units are used made, modular, skidded in automated or semi-automated Models as per the expected time cycle for washing and sterilization as a part of cGMP conditions from compact to long fixed Multi-Tank way.Salient Features of CIP System

- Sanitary Design to meet all cGMP criteria

- Contact portions: Mirror polished & EP to < 0.5 Micron finish, SS 316 L.

- All Non- Contact portions: Matt finish SS 304

- Orbital Tube welding

- Automation as per MCA & USFDA 21 CFR Part 11

- Built to custom requirement

- 100% Drianability

- GMP documentation like FAT, IQ, DQ, OQ & PQ Protocols

- Site Installation & Commissioning

- Documented Output of cleaning & sterilization cycles

SCOPE OF CIP UNIT

- CIP Tanks, Jacketed/Non-Jacketed/PHE

- Supply Pump/Return Pump

- Heater as required

- Dosing Tanks/Pumps

- Inter-connected Pipings / Valves / Instrumentation

- Automation System/Control Panel

- SS Skid/SS Platform

SCOPE OF MOBILE SIP UNIT

- Pure Steam Header comes with PI, TI & Safety Valve

- Condensate Header with Temp. Sensor and sterile steam trap unit

- PLC Control Panel with Time / Temperature control program, alarm, printer, etc. as needed

- SS Mobile Stand with PU Castors

We supply and export in the following countries:

- Russia

- Africa

- Latin America

- Bangladesh

- Egypt

- Ghana

- Iran

- Iraq

- Indonesia

- Malaysia

- Nepal

- Nigeria

Reviews

There are no reviews yet.