A toothpaste manufacturing plant is a facility where toothpaste is made. Toothpaste manufacturing is a process that begins by mixing the ingredients in a mixing tank. The mixture is then passed through a filler, which adds air and water to the powder. The toothpaste is then compressed into tubes using a toothpaste machine or extruded into tubes using an extruder. Once the toothpaste has been made, it is packaged and labeled before being shipped off to retailers.

A toothpaste manufacturing plant is a facility where toothpaste is made. Toothpaste manufacturing is a process that begins by mixing the ingredients in a mixing tank. The mixture is then passed through a filler, which adds air and water to the powder. The toothpaste is then compressed into tubes using a toothpaste machine or extruded into tubes using an extruder. Once the toothpaste has been made, it is packaged and labeled before being shipped off to retailers.

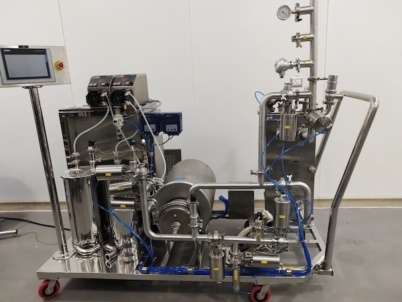

Toothpaste Manufacturing Equipment

Toothpaste manufacturing equipment includes various machines and processes that are used to make toothpaste. The first step in this process is mixing all of the ingredients together. This can be done manually or with an automatic mixer. Once mixed, the mixture is placed into a filling machine that injects air into the center of each tube of toothpaste before filling it with paste. This process allows more air bubbles to form in order to provide better flavor release when chewing on your toothbrush after brushing your teeth.

After filling, each tube is sealed shut with caps that are crimped onto both ends of each tube using mechanical crimpers or crimping machines. After crimping, each tube goes through a labeling process before being boxed up for shipment to retailers around the world!

Enquiry Now

A toothpaste manufacturing plant is a facility where toothpaste is made. Toothpaste manufacturing is a process that begins by mixing the ingredients in a mixing tank. The mixture is then passed through a filler, which adds air and water to the powder. The toothpaste is then compressed into tubes using a toothpaste machine or extruded into tubes using an extruder. Once the toothpaste has been made, it is packaged and labeled before being shipped off to retailers.

A toothpaste manufacturing plant is a facility where toothpaste is made. Toothpaste manufacturing is a process that begins by mixing the ingredients in a mixing tank. The mixture is then passed through a filler, which adds air and water to the powder. The toothpaste is then compressed into tubes using a toothpaste machine or extruded into tubes using an extruder. Once the toothpaste has been made, it is packaged and labeled before being shipped off to retailers.

Toothpaste Manufacturing Equipment

Toothpaste manufacturing equipment includes various machines and processes that are used to make toothpaste. The first step in this process is mixing all of the ingredients together. This can be done manually or with an automatic mixer. Once mixed, the mixture is placed into a filling machine that injects air into the center of each tube of toothpaste before filling it with paste. This process allows more air bubbles to form in order to provide better flavor release when chewing on your toothbrush after brushing your teeth.

After filling, each tube is sealed shut with caps that are crimped onto both ends of each tube using mechanical crimpers or crimping machines. After crimping, each tube goes through a labeling process before being boxed up for shipment to retailers around the world!