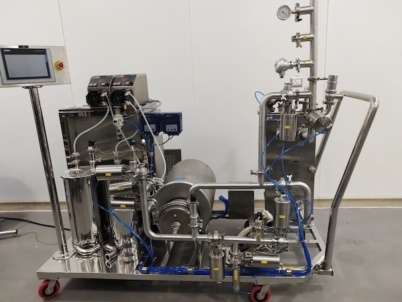

CIP system or Clean-in-place are an effective combination of machines and mechanical parts used to consolidate water, chemicals, and heat to generate cleaning solutions.

These chemical cleaning agents are circulated or pumped through other devices or components to clean them safely. These machines may be small hand-operated units that can use small vacuum tubes or large industrial pieces of machinery such as separators, vibrating machines, distillation units and vibratory coolers.

All of these machines have a common factor, i.e. that they require water for their proper functioning, either through a liquid or gaseous source.

Several countries have introduced various types of clean-in-place CIP systems that include activated carbon and charcoal filters that effectively remove chemical contaminants from tap water.

They improve the taste and odour of tap water. In India, different types of agencies and organizations, including drinking water associations, have various standards for drinking water, and these have been developed based on scientific facts and studies regarding health hazards associated with drinking water.

Clean-in-place CIP systems help to meet these standards. The certification provided by agencies ensures that the water source does not pose any danger to health.

Clean-in-place CIP systems use various technologies such as activated carbon, ion exchange, sub-micron filtration, catalytic reduction and solvent extraction. Some of the common ingredients or contaminants in drinking water sources include volatile organic chemicals (VOCs), lead, cysts, bacteria, fungi, chlorine and adenocarcinoma.

A standard method of reducing these chemicals in drinking water is adsorption, wherein the substances are adsorbed onto the surface of the CIP system. Other techniques used include kinetic energy generation, chemical reaction and chemical energy loss. Kinetic energy is harnessed to generate steam through distillation, while chemical reactions produce carbon dioxide, oxygen, and hydrogen.

Enquiry Now

CIP systems or Clean-in-place are an effective combination of machines and mechanical parts used to consolidate water, chemicals, and heat to generate cleaning solutions.

These chemical cleaning agents are circulated or pumped through other devices or components to clean them safely. These machines may be small hand-operated units that can use small vacuum tubes or large industrial pieces of machinery such as separators, vibrating machines, distillation units and vibratory coolers.

All of these machines have a common factor, i.e. that they require water for their proper functioning, either through a liquid or gaseous source.

Several countries have introduced various types of clean-in-place CIP systems that include activated carbon and charcoal filters that effectively remove chemical contaminants from tap water.

They improve the taste and odour of tap water. In India, different types of agencies and organizations, including drinking water associations, have various standards for drinking water, and these have been developed based on scientific facts and studies regarding health hazards associated with drinking water.

Clean-in-place CIP systems help to meet these standards. The certification provided by agencies ensures that the water source does not pose any danger to health.

Clean-in-place CIP systems use various technologies such as activated carbon, ion exchange, sub-micron filtration, catalytic reduction and solvent extraction. Some of the common ingredients or contaminants in drinking water sources include volatile organic chemicals (VOCs), lead, cysts, bacteria, fungi, chlorine and adenocarcinoma.

A standard method of reducing these chemicals in drinking water is adsorption, wherein the substances are adsorbed onto the surface of the CIP system. Other techniques used include kinetic energy generation, chemical reaction and chemical energy loss. Kinetic energy is harnessed to generate steam through distillation, while chemical reactions produce carbon dioxide, oxygen, and hydrogen.