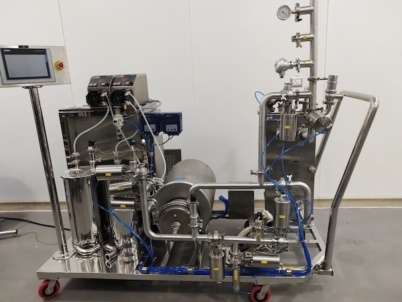

Rapid mixing granulator has become an essential part of recent days in pharmaceuticals, due to their unique feature. It can be used for various types of Pharmaceutical products, but most commonly, it is used to manufacture medicines.

Rapid mixing granulator has become an essential part of recent days in pharmaceuticals, due to their unique feature. It can be used for various types of Pharmaceutical products, but most commonly, it is used to manufacture medicines.

Most of the rapid mixing granulators come with steel balls. The main aim behind the manufacturing of rapid mixing granulators is to produce a powdered form of the drug. These immediate mixing tablets are required to undergo a series of tests and inspections by various medical bodies and government agencies for safety purposes.

Rapid mixing granulators come with various types of features. For example, some of them come with needleless design; there is also a wet granulation high shear mixing device that comes with stainless steel ball bearings and screw threads to suit the requirements of high pressure, high shear rapid mixing tablets. Maharashtra, a drug manufacturing company, has introduced the high-quality wet granulation immediate mixing tablet.

This tablet is manufactured as per international GMP standards. High shear rapid mixing granulator is designed and engineered for use in a wide range of tablet mixers, including capsules, tablets, liposomes, powders, suspension solutions, elixirs, lozenges, chewing gums, mucous preparation mixes, ointments, shampoos, lubricants, cushions, gels, creams, lotions, skin patches etc.

This tablet’s high shear mixing feature helps in quick, efficient mixing and instant release of all Tablet ingredients. This type of tablet also features a safety lift lid with anti-tip action. This safety lift lid design prevents accidental spillage of the contents of the tablet.

Enquiry Now

In recent days, rapid mixing granulator has become an essential part of pharmaceuticals, due to their unique feature. It can be used for various types of Pharmaceutical products, but most commonly, it is used to manufacture medicines.

In recent days, rapid mixing granulator has become an essential part of pharmaceuticals, due to their unique feature. It can be used for various types of Pharmaceutical products, but most commonly, it is used to manufacture medicines.

Most of the rapid mixing granulators come with steel balls. The main aim behind the manufacturing of rapid mixing granulator is to produce a powdered form of the drug. These immediate mixing tablets are required to undergo a series of tests and inspection by various medical bodies and government agencies for safety purpose.

Rapid mixing granulators come with various types of features. For example, some of them come with needleless design; there is also a wet granulation high shear mixing device that comes with stainless steel ball bearings and screw threads to suit the requirements of high pressure, high shear rapid mixing tablets. Maharashtra, a drug manufacturing company, has introduced the high-quality wet granulation immediate mixing tablet.

This tablet is manufactured as per international GMP standards. High shear rapid mixing granulator is designed and engineered for use in a wide range of tablet mixers, including capsules, tablets, liposomes, powders, suspension solutions, elixirs, lozenges, chewing gums, mucous preparation mixes, ointments, shampoos, lubricants, cushions, gels, creams, lotions, skin patches etc.

This tablet’s high shear mixing feature helps in quick, efficient mixing and instant release of all Tablet ingredients. This type of tablet also features a safety lift lid with anti-tip action. This safety lift lid design prevents accidental spillage of the contents of the tablet.