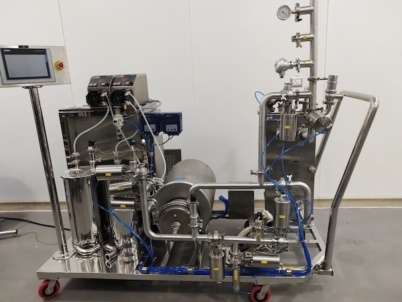

Rapid Mixer Granulator Diagram represents the rapid mixing process and the various types of granules available in the market. This diagram depicts the function of each component in the granulation process. It also helps the users to understand the different types of granulators available and their functionality. The granulation product is made up of powder, which is suspended in an injector.

In the process, the granules are injected into the injector, and the granules are separated into two flights by the injector. The two flights are then transferred to the mixing device. Here the mixing device combines the two granules, and the suspension becomes a powder. The final product is then sent to a drying chamber where it is dried using heat or cold airflow.

The diagrams show the different types of granules. It also shows how the granules get dissolved. It explains why it is essential to choose the right kind of powder.

For instance, dry dust is needed for wet granulation, ultra-fine dust is necessary for ultra-fine dust, and wet granulation and emulsifiers are needed for both dry and wet granulation. The rapid mixer granulator machine is therefore very essential for all industries that need to granulate.

The basic purpose of the Rapid Mixer Granulator Diagram is to help consumers understand how this machine works so that they can decide whether this machine would be suitable for their needs or not.

Enquiry Now

Rapid Mixer Granulator Diagram represents the rapid mixing process and the various types of granules available in the market. This diagram depicts the function of each component in the granulation process. It also helps the users to understand the different types of granulators available and their functionality. The granulation product is made up of powder, which is suspended in an injector.

In the process, the granules are injected into the injector, and the granules are separated into two flights by the injector. The two flights are then transferred to the mixing device. Here the mixing device combines the two granules, and the suspension becomes a powder. The final product is then sent to a drying chamber where it is dried using heat or cold airflow.

The diagrams show the different types of granules. It also shows how the granules get dissolved. It explains why it is essential to choose the right kind of powder.

For instance, dry dust is needed for wet granulation, ultra-fine dust is necessary for ultra-fine dust, and wet granulation and emulsifiers are needed for both dry and wet granulation. The rapid mixer granulator machine is therefore very essential for all industries that need to granulate.

The basic purpose of the Rapid Mixer Granulator Diagram is to help consumers understand how this machine works so that they can decide whether this machine would be suitable for their needs or not.