Liquid oral manufacturing plant is a modern pharmaceutical production unit. A pharmacist, physician or drug manufacture officer performs the actual manufacture of medications and other pharmaceutical products. These plants can be found in a hospital, at a factory, or in some remote location.

The liquid injection system used to manufacture this type of medication can be done by machines, known as the pharma press, or by using humans as testers for various drugs. In a traditional pharmaceutical plant, multiple chemical reagents, solvents and enzymes are used before administering medication. In contrast, in the liquid & oral manufacturing plants, only drinks are manufactured.

To produce the medicine, the manufacturer must know the exact requirements of the product to be made. This includes the correct amount and kind of sugar needed, the proper amount of water, the right temperature and quality of sterile water, and other factors.

The liquid oral manufacturing plant also ensures that the medication’s ingredients will interact well and produce only the best product. Other factors that are important in determining the result of any oral manufacturing process include the likes and dislikes of the customers, the specifications of the products to be manufactured and the manufacturer’s experience and skills.

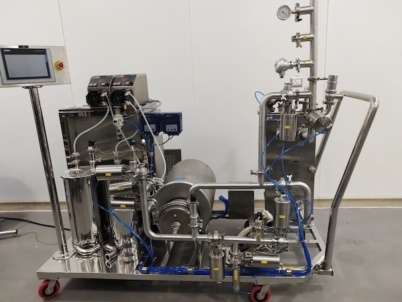

The liquid manufacturing plant employs several machines and tools to help in the manufacture of medicines. For instance, a liquid & oral manufacturing plant can utilize three types of devices: the protein crystal lattice manufacturer, the protein folding machine, and the microfiltered filter press.

The most commonly used equipment in this industry is the protein crystal lattice manufacturer. Protein crystals are manufactured using the protein folding machine, which is the most crucial step in this entire process. The manufacture of the liquid requires a filter press that separates the solids from the liquids. Lastly, to keep the processing line of the pharmaceutical industry running smoothly, it is imperative to ensure that the correct temperature is maintained.

Enquiry Now

Liquid oral manufacturing plant is a modern pharmaceutical production unit. A pharmacist, physician or drug manufacture officer performs the actual manufacture of medications and other pharmaceutical products. These plants can be found in a hospital, at a factory, or in some remote location.

The liquid injection system used to manufacture this type of medication can be done by machines, known as the pharma press, or by using humans as testers for various drugs. In a traditional pharmaceutical plant, multiple chemical reagents, solvents and enzymes are used before administering medication. In contrast, in the liquid & oral manufacturing plants, only drinks are manufactured.

To produce the medicine, the manufacturer must know the exact requirements of the product to be made. This includes the correct amount and kind of sugar needed, the proper amount of water, the right temperature and quality of sterile water, and other factors.

The manufacturer also ensures that the medication’s ingredients will interact well and produce only the best product. Other factors that are important in determining the result of any oral manufacturing process include the likes and dislikes of the customers, the specifications of the products to be manufactured and the manufacturer’s experience and skills.

The liquid manufacturing plant employs several machines and tools to help in the manufacture of medicines. For instance, a liquid & oral manufacturing plant can utilize three types of devices: the protein crystal lattice manufacturer, the protein folding machine, and the microfiltered filter press.

The most commonly used equipment in this industry is the protein crystal lattice manufacturer. Protein crystals are manufactured using the protein folding machine, which is the most crucial step in this entire process. The manufacture of the liquid requires a filter press that separates the solids from the liquids. Lastly, to keep the processing line of the pharmaceutical industry running smoothly, it is imperative to ensure that the correct temperature is maintained.