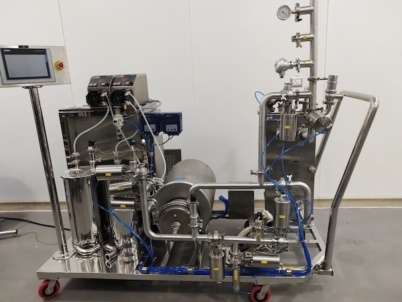

Contra mixers are used in a wide variety of industries, including the pharmaceutical industry. Contra mixers are typically used for powder handling applications. They are used to mix dry materials or liquids with different densities, like water and petroleum oil. The material being mixed is usually contained within a rotating drum that is rotated at high speeds by an electric motor.

Contra mixers are used in a wide variety of industries, including the pharmaceutical industry. Contra mixers are typically used for powder handling applications. They are used to mix dry materials or liquids with different densities, like water and petroleum oil. The material being mixed is usually contained within a rotating drum that is rotated at high speeds by an electric motor.

The speed of rotation is controlled by a variable frequency drive (VFD). The VFD controls both the speed of rotation and the torque applied to the shaft of the mixer. This allows for precise control over how much energy is applied to each batch as it is being mixed.

Contra mixers are used in many different types of industries because they offer several benefits over traditional mixing methods. These include:

Increased efficiency – Contra mixers use less energy than other methods, making them more efficient and cost effective than other mixing methods such as paddle mixers or plowshare mixers

High throughput – Contra mixers have high throughput capabilities that allow you to handle large batches quickly and easily

Low maintenance – Contra mixers require very little maintenance compared

Enquiry Now

Contra mixers are used in a wide variety of industries, including the pharmaceutical industry. Contra mixers are typically used for powder handling applications. They are used to mix dry materials or liquids with different densities, like water and petroleum oil. The material being mixed is usually contained within a rotating drum that is rotated at high speeds by an electric motor.

Contra mixers are used in a wide variety of industries, including the pharmaceutical industry. Contra mixers are typically used for powder handling applications. They are used to mix dry materials or liquids with different densities, like water and petroleum oil. The material being mixed is usually contained within a rotating drum that is rotated at high speeds by an electric motor.

The speed of rotation is controlled by a variable frequency drive (VFD). The VFD controls both the speed of rotation and the torque applied to the shaft of the mixer. This allows for precise control over how much energy is applied to each batch as it is being mixed.

Contra mixers are used in many different types of industries because they offer several benefits over traditional mixing methods. These include:

Increased efficiency – Contra mixers use less energy than other methods, making them more efficient and cost effective than other mixing methods such as paddle mixers or plowshare mixers

High throughput – Contra mixers have high throughput capabilities that allow you to handle large batches quickly and easily

Low maintenance – Contra mixers require very little maintenance compared